You can find the test reports online here.

FAQs

Here are the FAQ list about dasso, bamboo, decking or whatever you can image.

-

Where can I find the test reports?

-

What products does dasso group sell?

We offer a whole range of bamboo, from decking, cladding, soffit to panelings and veneers.

-

What is dassoXTR?

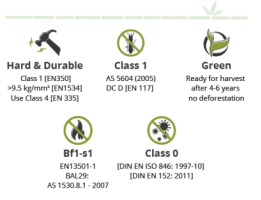

dassoXTR is a fused exterior bamboo product made using our patented process, which combines two stages of high heat to first carbonize the bamboo, removing all of the starch and sugar, and then restructure the bamboo, reinforcing its natural strength characteristics. The modified bamboo strands are then fused together using phenolic resin – the same resins used to make bowling balls. The result is an extremely dense, durable exterior-use product composed of 87% natural, fused strand bamboo fibers and 13% resin (or as we like to say, 13% bowling ball).

While technically a composite material, dasso.XTR looks and reacts much like other natural wood products, specifically Ipe hardwood. But, because bamboo does not include rays or knots like natural woods, dasso.XTR has a much more flawless appearance than other decking materials made from woods. This consistent grain structure also allows dasso.XTR to distribute weight very evenly, adding to its durability.

-

What is dassoCTECH?

dassoCTECH is a fused exterior bamboo product made using our patented process, which is called CeramiX® process. We crystalize the bamboo fibers with CeramiX® particle, impregnate it with phenolic resin (the same resin found in bowling balls), then compress it 2:1 to form Fused Bamboo. Because Fused Bamboo is now fully impregnated with CeramiX® particle that crystalizes the nutrients from attracting bacteria, fungus, molds or insects, the fiber does not rot under exposed environments.

-

How is fused bamboo different from traditional bamboo decking?

There are a number of processes that can be used to turn stalks of bamboo into planks for decking. Most manufacturers either take long strips of bamboo and laminate them together or shred the bamboo and compress it with glue. Both of these processes lead to a product that doesn’t hold up well when exposed to weather: laminated bamboo strips are prone to cupping and separating, while compressed shredded bamboo is often brittle and will quickly degrade when exposed to the elements.

-

Why is dasso’s fused process so effective?

During the patented fused process, sugar and starch are extracted from the bamboo fiber, leaving only the bamboo cell wall. Without these nutrient and food sources, fungus will not attach to the bamboo cells and grow, thereby eliminating the breakdown of the cell walls – which is the cause of rot. Without a nutrient source, insects also are not attracted to the material, which further protects the bamboo from decay.

All bamboo must be carbonized, or heat treated, before it can be used outside. However, when bamboo is heat treated it gets very brittle. dasso’s patented process eliminates this issue by applying a second heating stage. During this stage, lignum, a natural binder found in the bamboo fiber, is melted and reset, returning the bamboo to its natural rigidity. This increased strength produces a denser, harder board, while still maintaining bamboo’s natural characteristics.

-

How does dasso fused bamboo compare to other exterior building materials?

dasso’s remarkable durability makes it a unique material for use in outdoor construction materials, including decking, siding, and furniture. In fact, dasso fused bamboo products are among the stiffest and strongest decking materials in the world and is even more dense than Ipe – a natural wood that is widely accepted for outdoor use. dasso’s bamboo products are also Class A Fire rated using C NFPA and IBC Classifications tested to ASTM E-84-12 and decay and insect resistant (including resistance to termites).

Tested in accordance with International Code Council (ICC) standard AC174 for exterior decking, dasso’s fused bamboo products has been approved/accepted as a product suitable for exterior usage.

To find out more about how dasso’s fused bamboo products stacks up against other popular decking materials, see the test reports here.

-

Is dasso’s fused bamboo products considered an environmentally friendly product?

Yes. Unlike most hardwoods, which must grow for 50 years or more before they can be harvested, bamboo is a fast-growing grass that can be harvested every 4-6 years. This makes bamboo one of the most environmentally friendly and sustainable building products available. As a product made from a rapidly renewable material with a harvest cycle of less than 10 years, dasso fused bamboo material is eligible for an MR-6 LEED Credit, which is the highest credit available for renewable materials. In addition, the resins used to create dasso fused bamboo products are thermal setting and non-reversible, which means no fumes are released into the atmosphere. Thus, dasso fused bamboo products - dassoXTR & dassoCTECH contains no volatile organic compounds (VOCs).

-

Does dasso fused bamboo products include a factory finish?

dasso fused bamboo products - decking, porch flooring and siding receive one coat of WOCA exterior oil at the factory, which gives the boards their color and provides some surface protection. The lumber and panels come unfinished and need to be finished after installation/application.

Lumber and panels are to be considered as "rough and unfinished" requiring further processing to get a final product.

-

How long will the factory-finish on decking last?

The first coat of WOCA exterior oil typically wears off the board faces during or shortly after the construction phase and when exposed to sun, rain, dirt, and wear.

-

Does dasso fused bamboo material fade?

dasso fused bamboo material behaves much like a natural building material. If left untreated, including when the decking's first oil coat wears off, boards will eventually turn a silver-grey patina, usually after about 12-18 months. Therefore, dasso fused bamboo products need to be maintained similar to exotic hardwoods. Please see our section on our website.

-

Do I have to finish dassoXTR & dassoCTECH?

If you want the material to turn silver-grey, then no additional finish is needed. However, we recommend applying a penetrating finish soon after installation for UV protection. Please see our section on the website to learn more about timing and types of finishes..

-

What type of exterior finish is recommended?

We recommend using a finish much the same as those used on tropical hardwoods – either a penetrating oil or a synthetic surface finish.

-

What is the recommended maintenance?

Evaluate finish each spring and maintain as needed, following the finish brand’s instructions. Finish durability depends upon weather, wear and other local conditions. A penetrating oil finish typically lasts 1–3 years on decks and 2–4 years on siding, a synthetic surface coating/stain typically lasts 1–2 years on decks and 1–3 years on siding.

-

Explain dasso’s bamboo decking end-matching system.

All of our bamboo decking includes a unique tongue and groove End Match System, whereby each board is end-matched for ease and improved quality of installation. This allows a better aesthetic because end joints are not required to meet "on a joist" thereby offering a more random pattern. Not having to meet all the deck boards on a few joists, and showing an unappealing all-board-ends-lined-up with the joists installation problem, allows you to save time and money on installation. It also produces a stronger, more beautiful-looking deck with flawless, consistent coloration.

In addition, all boards are side grooved for hidden fastening but can also be face screwed and plugged instead. Boards are available in single-groove or double-groove constructions and offered in a reversible profile that is smooth on one side and reeded on the other, offering you a choice of two installation options – smooth side up for a sleek look, or reeded face up for a more textured style.

-

Where can I buy dasso fused bamboo products?

USA: We currently stock dasso fused bamboo products in Atlanta, and more is arriving in New Jersey and Oregon.

China: We have a dealer locator on our site and a Rep locator if a dealer is not available in your immediate area.

-

How do I order samples?

Sample requests should be emailed to info@dassogroup.com or by submitting your request online here.